Case Study:

Automated COVID19 Compliance for Global Food Manufacturers

The situation became critical for our client, a global food manufacturer, when staff reported temperature guns getting inaccurate readings as low as 28 degrees on entering visitors. These frustrating errors meant two staff members needed to be stationed on each entrance at all times, in order to ‘double test’ each person. These staff members had to come into close proximity with other individuals to take temperatures and were at high risk of infection. The manufacturer prides themselves on rallying together in times of challenge and was committed to finding a safe solution for protecting their employees.

Xacom began investigating a solution that would relieve the administrative burden of manual temperature checking for our client. We also wanted to be able to guarantee the highest level of accuracy and safety. Through a collaborative process, together we developed a solution.

Xacom Active Fever Detection System |

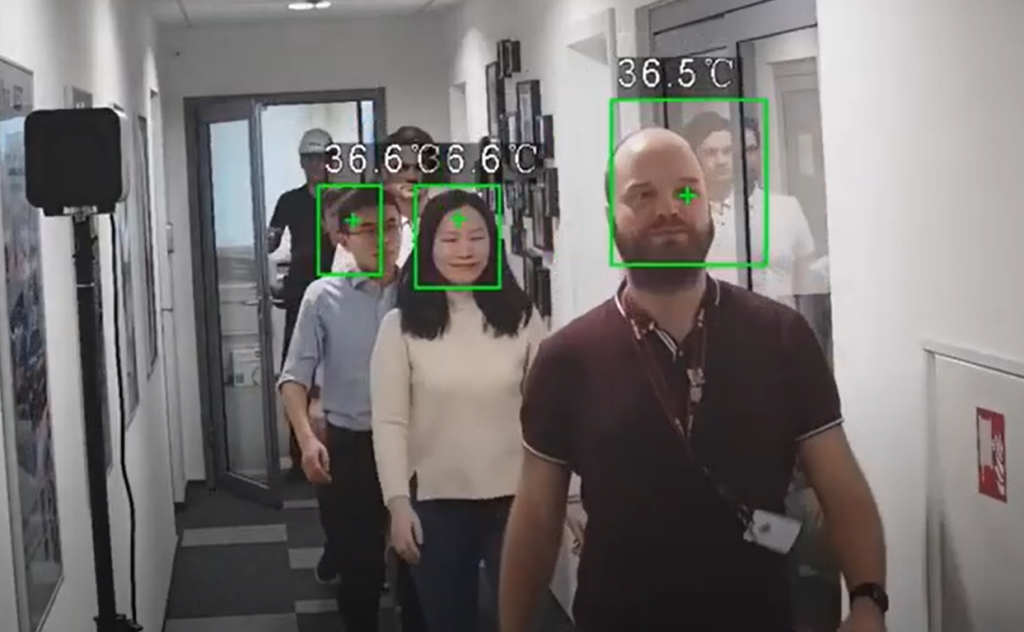

A thermal camera system that alerts for high temperatures in approaching individuals, which integrates with other critical communication systems. The system’s flexibility allows for its temperature detection features to be used for any or all of the following:

|

The system addressed the corporation’s needs in the following ways:

Challenge | Solution |

High traffic environment | AI powered processing is able to process 5+ concurrent faces in 0.2 seconds from 3+ metres away |

Heavy administration burden on staff | The automated system instantly measures temperature and time, sending instant alerts of fever risks with images and timestamps to relevant staff as well as alerting locally |

Opportunity for Increased Safety | Temperature accuracy of +-0.3 degrees and access control integration to restrict building access to at risk individuals |

"The global food manufacturer was immediately able to remove a staff member from each temperature detection station."

The Results: The global food manufacturer was immediately able to remove a staff member from each temperature detection station, enabling them to get back to their regular tasks. Additionally, the remaining staff member was no longer at risk of coming into contact with a COVID positive individual as the system automated the temperature reading and they could stand back and supervise the process. Many other staff were able to get back to their regular roles as they could trust the system to alert them when it needed attention and they were able to be notified of alerts from their email inboxes. The corporation decided to install the system in five of their facilities and at multiple entrances for some of them. Over the coming weeks many staff, visitors and contractors were denied entry, keeping the facilities safer and allowing them to efficiently meet external regulatory requirements.